Products and Services

Solution

2025-07-03

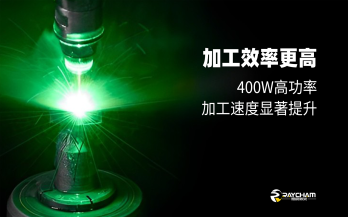

此次展会,中科煜宸将展示两大核心技术:激光焊接与金属增材制造,为汽车制造企业提供...

2025-06-26

近日,在激光加工行业备受瞩目的 2025 年激光加工行业荣格技术创新奖颁奖典礼上...

2025-05-07

4月21日,第十九届中国国际机床展览会(CIMT2025)在北京新国展盛大启幕。...

2025-04-09

作为中国高端智能装备与激光制造技术领域的领军企业,中科煜宸将携多款创新产品与...

2025-03-17

2025年3月17日,TCT亚洲展在上海国家会展中心7.1&8.1馆盛...

2025-03-05

目前,风力发电机齿轮箱的失效故障占风力发电机总失效故障的40%,是风力发电机主要...

2025-01-20

01.与苏美达签署战略合作协议1月7日,南京中科煜宸激光技术有限公司(以下简称“...

2024-12-28

2024年12月27日,南京中科煜宸激光技术有限公司(以下简称“中科煜宸”)与本...

2024-11-29

11月28日,2024中国激光星锐奖新鲜出炉,中科煜宸“五轴联动水导激光加工设备...

ABOUT US

南京中科煜宸激光技术有限公司成立于 2013 年,是一家专业从事激光增材制造(送粉3D打印、铺粉3D打印、增减材打印、激光修复)、智能激光加工(激光焊接自动化、水导激光)、核心器件及系列化工业软件的研发与制造的国家级专精特新小巨人企业,公司致力于为世界500强国内外制造企业提供完善的智能激光加工系统解决方案。

了解更多 +激光增材制造行业经验

国家专利

国家级重大专项

研发技术人员

300+ 高端客户认可