Products and Services

Solution

2024-04-09

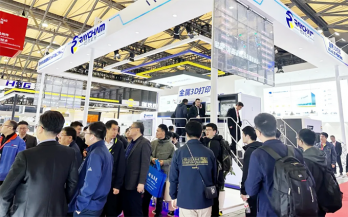

中科煜宸携金属3D打印、水导激光加工等技术解决方案亮相展会,展出了RS450F铺...

2024-03-07

针对增材制造过程需要全生命周期数据追溯、关键参数实时采集监控、物料批次追溯等需求...

2024-01-23

1月17日,河钢工业技术服务有限公司(以下简称“河钢工业技术”)、西门子(中国)...

2023-11-29

中国激光星锐奖旨在表彰对激光技术发展做出卓越贡献的企业和产品,在激光行业内极具影...

2023-11-17

11月16日,中国机床工具工业协会特种加工机床分会2023年会员大会在成都成功举...

2023-10-27

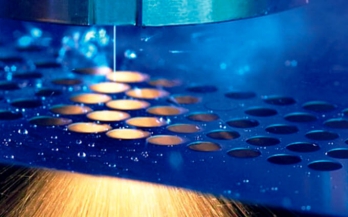

水导激光技术是一种绿色、高效、无损伤的加工技术,可用于金属、陶瓷、金刚石、热障涂...

2023-10-16

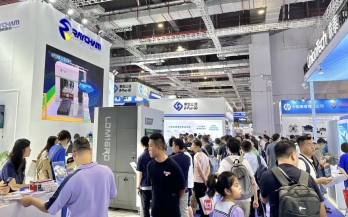

2023 TCT亚洲展于9月12日在上海国家会展中心拉开了帷幕,中科煜宸携多款重...

2023-10-16

9月23日,国家重点研发计划“增材制造与激光制造”专项“大型高性能结构件增等减材...

2023-08-09

相较于传统切割和超快激光等加工技术,水导激光技术具有μm级热影响区、微小的锥度、...

ABOUT US

南京中科煜宸激光技术有限公司成立于2013年,是一家专业从事激光增材制造装备(3D 打印机、激光修复)、智能激光焊接装备、自动化生产线、核心器件的研发与制造的国家级高新技术企业。公司立足于自主创新,致力于打造激光完整产业链,逐步在东北、华东、华中、西南区域分别布局建设了研发中心、应用示范中心、营销中心及加工制造服务基地。

了解更多 +激光增材制造行业经验

国家专利

国家级重大专项

研发技术人员

300+ 高端客户认可